You’re washing your hands, staying at home as much as you can and wearing a mask when you must go out. But you can still feel helpless, especially when a family member is on the front lines, caring for COVID-19 patients. Schmid College student Alexandros Drivas ‘21 and his younger brother, Matt, knew they had to do something to help after hearing stories from their mother, an emergency medicine physician assistant who works long hours at a hospital in Los Angeles County.

“Every day we hear about the battles she and her co-workers face, given COVID-19,” Drivas said. “We hear about the scarce levels of equipment her hospital and all other hospitals around the country [are facing].”

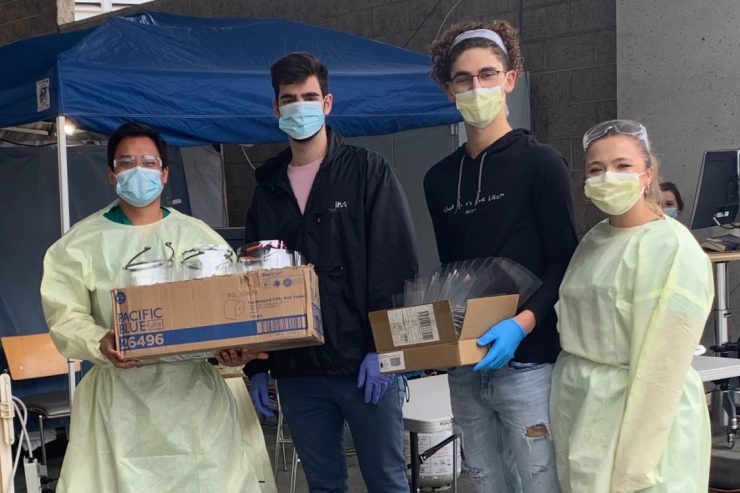

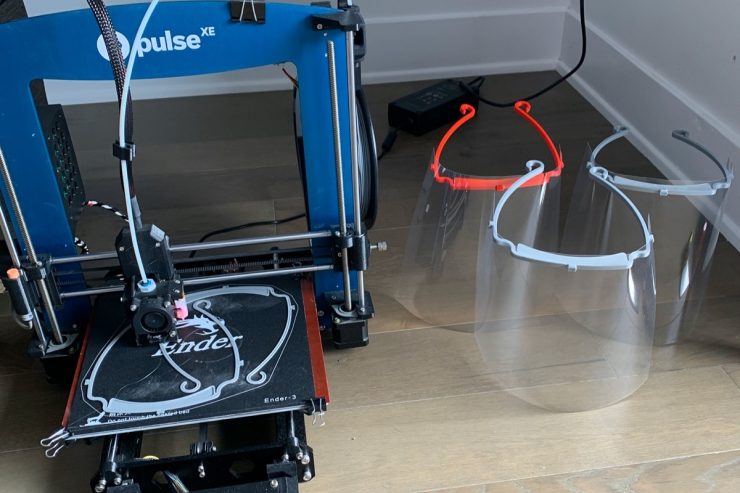

To protect their mother and other healthcare workers, the Drivas brothers started 3D printing face shields and distributing them to local Southern California hospitals. Their efforts are part of a larger mobilization by Chapman students and faculty.

Chapman is collaborating with Orange County-based MatterHackers – which builds and supplies 3D printing equipment – to coordinate distribution to local hospitals.

The face shields are part of vital protection healthcare workers need to stay safe as they treat patients.

“If a hospital staff member catches the virus, their health is at serious risk, and they cannot work for at least 14 days,” Alex Drivas said. “That’s a major problem.”

A Real-Life Grand Challenge

As a biochemistry and molecular biology student, Drivas participated in Chapman University’s Grand Challenges Initiative, which is a unique two-year program for all incoming first-year students in Schmid College of Science and Technology and Fowler School of Engineering. Through the program, the students work in teams along with a faculty mentor to solve the world’s most pressing problems. Projects range from reverse-engineering the brain to improving data security.

The program has a Makerspace on campus where students gain hands-on experience with sophisticated equipment, including 3D printers. “We want to empower [our students] to have the confidence to get their hands dirty and make a difference in the world around them,” said Gregory Goldsmith, director of the Grand Challenges Initiative.

“The program provided me with resources to study 3D printing,” Drivas said, “and it enhanced the critical-thinking and problem-solving skills needed to try to make a difference.”

Drivas previously has designed 3D printed equipment to advance research along with Grand Challenges Initiative post-doctoral fellow Carter Berry.

Going Above and Beyond

So far, the Drivas brothers have distributed 50 face shields to doctors, nurses and physician assistants at St. John’s Hospital in Los Angeles. Now they’re making 50 more for a local urgent care organization.

By creating the face shields using 3D printers, manufacturing costs stay low, less than $1 per unit. However, the brothers still needed money for supplies in hopes to make a broader impact. This led them to create a Go Fund Me page to collect donations.

“This effort would not have been possible without the support of our friends, family and the Chapman community,” Drivas acknowledged.

Within 24 hours of creating the Go Fund Me page, they were able to raise more than $2,000. You can read more about their efforts on their Go Fund Me page.

“Alex has found a passion for engineering and is not afraid to rally people around a cause,” noted Goldsmith. “I don’t think that this is the last time you’ll hear about Alex; he embodies the next generation of leaders in science and engineering.”

A time-lapse video shows how the 3D printing process creates frames for the face masks.